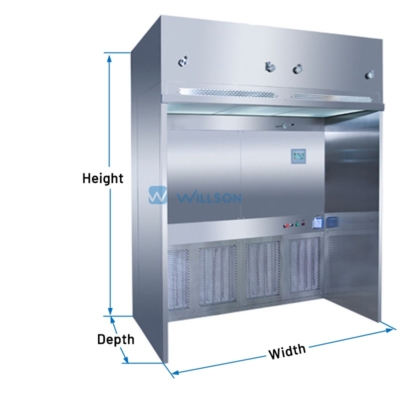

Dispensing booth, also know as reverse laminar air flow (RLAF), sampling booth, weighing booth or down-flow booth, is mainly applicable to pharmaceutical, food and healthcare industries. it is designed to provide vertical laminar airflow to work area, most of air is recycled within booth, partial air is exhausted, so as to make working area in negative pressure state, thus containing particles or powder from overflowing outside of booth when weighing or sampling raw materials are conducted inside booth. More importantly, the negative pressure booth can protect worker’s health from inhaling particles or powders.

Control Modes

According to control mode, our downflow booth has two versions:

1: Standard Version: Varied Frequency Device (VFD)-control Mode; 2: Advanced Version: PLC-control Mode

Features

-

- Negative pressure design to contain the powder inside booth

- 100% stainless steel 304 design, easy cleaning and GMP-compliant

- Top air supply with H14 HEPA filter, reaching air cleanliness of ISO-5/Class 100

- DOP test ports to test air leakage of HEPA filter

- Modular and disassembled design to enable easy transport and fast site assembly.

- Built-in sockets with plastic cover for the power supply of weighing or sampling devices and other electric appliance.

- Emergency button to power off the booth in case of emergency.