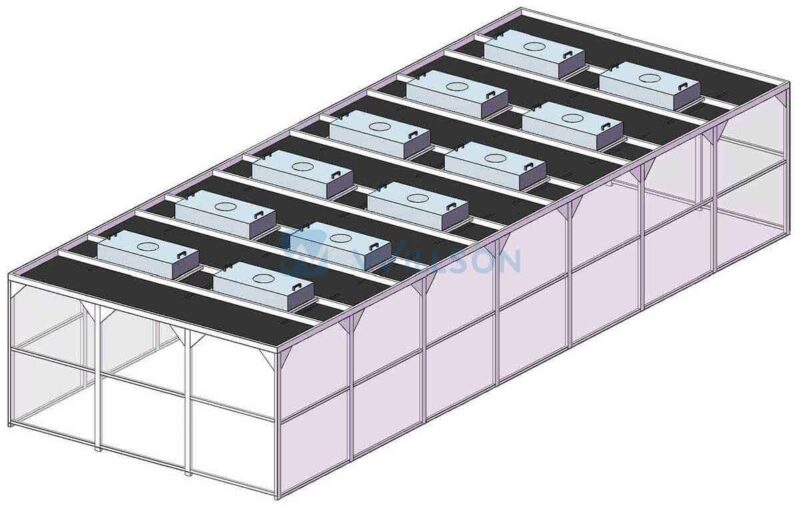

A soft-wall clean booth is a type of cleanroom that is designed to provide a controlled environment for various industries, including pharmaceuticals, biotechnology, electronics, and semiconductor manufacturing.

Compared with “hard-wall cleanroom“, a soft-wall clean booth is constructed using flexible materials such as anti-static PVC film or curtain that create a barrier between the cleanroom and the surrounding environment. The booth is equipped with fan filter unit(s) that draw(s) air through a HEPA or ULPA filter and directs it into the workspace, creating a positive pressure environment that prevents contamination from entering the workspace.

Soft-wall clean booths are designed to be portable and easy to assemble, making them an ideal choice for temporary cleanroom requirements or for use in the field. They are available in different sizes and configurations to accommodate various applications. Due to their versatility and ease of use, soft-wall clean booths are a popular choice for many industries that require a controlled environment to work with delicate samples or equipment.

Features:

- Provide high clean environment for local production area, with air cleanliness ranging from ISO4 to ISO8 (Class10-100,000)

- 100% customization, booth size based on production area of plan layout, booth frame and wall material

- The booth frame can be made of PCGI steel rail, aluminum rail, stainless steel rail.

- The soft wall can be made of anti-staic transparent PVC film or PVC curtain

- Positive pressure, keeping contaminant out of cleanroom

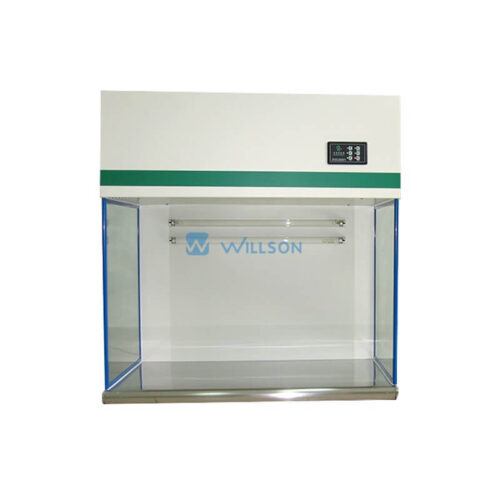

- Fan filter units(FFUs) working on top to blow laminar downflow airflow down to work area

- Air velocity adjustable, stepless speed adjustment or HMI screen control