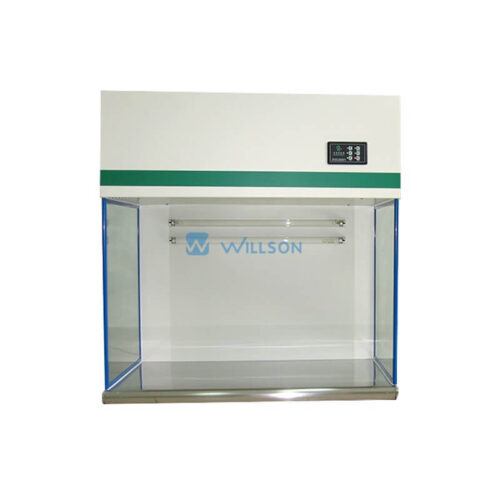

A vertical laminar flow clean bench is a type of cleanroom technology that is used to create a sterile and particle-free environment for various applications. These benches use a vertical flow of clean air to remove airborne contaminants and maintain a sterile working environment. The air is typically filtered through HEPA filters, which are designed to remove particles as small as 0.3 microns with an efficiency of 99.97%. Vertical laminar flow benches are commonly used in industries such as pharmaceuticals, biotechnology, and electronics manufacturing, where even small particles or contaminants can have serious consequences. They are also used in research laboratories and medical facilities to maintain a sterile environment for sensitive experiments and procedures.

According to the direction of filtered airflow, clean bench has two types, one is vertical laminar flow, another one is horizontal laminar flow.

Features:

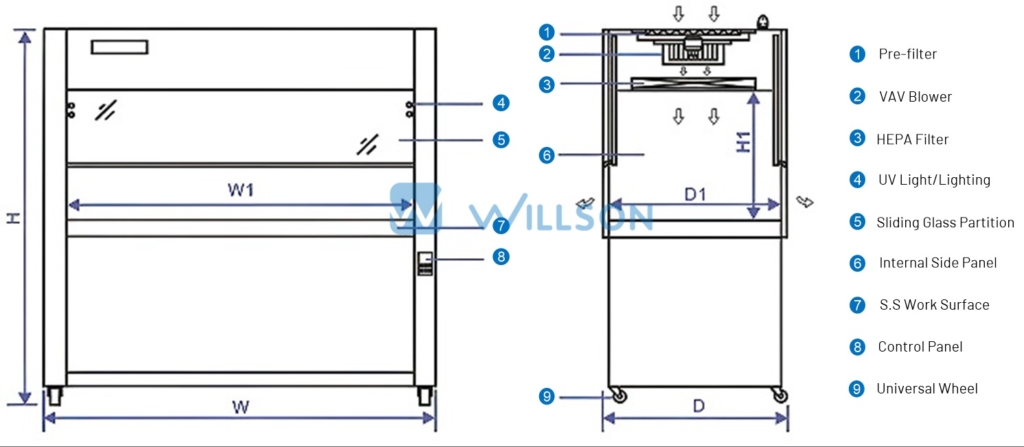

- Vertical laminar flow, 100% positive pressure coverage at work area, ensuring no external airflow coming into work area so as to protect the sample or product within work area.

- Varied air volume (VAV) blower and voltage regulation via feather-touch control panel to enable air velocity working at an ideal state within work area

- Light and UV light work in an interlocking way to protect operator

- The sliding glass partition is made of 5mm toughened glass, can be positioned at any level.

-

The work surface is made of SUS 304, corrosion-resistance and easy cleanning