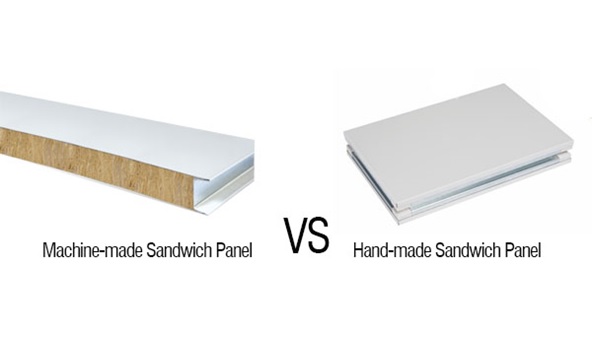

Before discussing the differences between hand-made and machine-made sandwich panels, let’s take a look at this image:

As you can see from the above image, the most apparent difference between the two types of panels is that the infill material (rock wool in the above examples) is visible on the width side of machine-made panels, but not on hand-made panels. Why? The answer will lie in the production process.

Let’s first talk about the production process of machine-made sandwich panel. As suggested from the name, machine-made sandwich panel is made 100% by a machine, without any manual operation, including pre-coated sheet cutting, bending, glue application, infill placement, pre-coated double-side sheets and infill compression.

Different from machine-made sandwich panel, hand-made sandwich panel has galvanized steel frame between two pre-coated sheets as an enclosure, the frame will be place before above-mentioned compression process (here below is our video showing how cleanroom hand-made sandwich panels are manufactured), that is, after automatic glue application, workers should manually place the G.I frame onto the glued sheet, manually place and cut the infill and make infill fully fill the frame, then go to next automatic operation like top pre-coated sheet coverage, then go to compression and backing process.

Video: “How cleanroom hand-made sandwich panels are manufactured?”

Since the hand-made sandwich panel is fully sealed by double-face pre-coated steel sheets and frame, you cannot see the infill after production. Here we are not saying you can still see the exposed infill after the machine-made sandwich panels are installed on site, actually you cannot see the exposed infills, as they will be covered by aluminum U-channel on site. The machine-made sandwich panels will sit into aluminum U-channels.

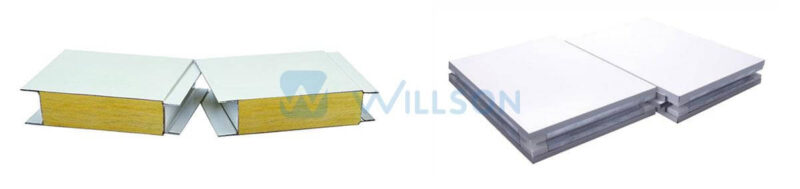

Now let’s see the panel-to-panel connection difference between machine-made panels and hand-made panels

For the connection of two machine-made sandwich panels, nothing is required, as you can see from the above image, the machine-made sandwich panel has male and female sides at two sides. When installation on site, just push one panel into another panel.

But for two hand-made sandwich panels, a “+”type aluminum connector (as showed below) will be required to insert into the slots on the galvanized frames of two hand-made sandwich panels.

From the structres of two kinds of panels, can you know which is more strong? Yes, you are right, the hand-made type is more strong or hardness. After all, hand-made panel is with enclosed frame in between two pre-coated steel sheets. The frame is actually as skeleton of the panel, make the handmade panel more strong and hard. This is why ceiling panels usually adopt hand-made sandwich panel. And can you know which type of panel is more flat and smooth? Obviously the hand-made panel prevails.

So what advantages the machin-made sandwich panel has? Compared to hand-made sandwich panel, the price of machine-made sandwich panel is lower, as you can see from the above, there are no galvanized steel frame(skeleton) and no “+” type galvanized steel connector. In addition to the price, the main advantage of machin-made panel is that installor can make cutouts for cleanroom windows or cleanroom doors at site, no worring to cut the panel seams. However, for hand-made panel, all dimensions must be accurate, the positions of doors and windows are fixed and cutting is not allowed on site, particaully cutting happen on the panel seams.

From the image above, can you tell which type of sandwich panels are used? Yes, they are machine-made sandwich panel. You can see the cutting happened onto the panel seams, and you can see aluminum plates around the window.

After making the cut-outs on the wall panel for the window, use the prefabricated powder-coated aluminum profile to cover and fix the window.

Now let’s look at hand-made sandwich panel with the cleanroom window.

As you can see from the above image, there is no aluminum plates around the window. The window width is the same as panel width, that means no cutting on the panel seams. Possibly you will ask how to fix the window onto the wall panels, the same as wall-to-wall panel connection, the above-mentioned “+” type aluminum connector should be used. You can see also there are aluminum frame in between two layer of tempered glass, with four slots around the window.

In conclusion, both hand-made and machine-made sandwich panels have their own advantages and disadvantages. Hand-made panels are stronger and more smooth, while machine-made panels are cheaper and allow for on-site cutouts. The production process and panel-to-panel connection also differ between the two types of panels. Ultimately, the choice between hand-made and machine-made sandwich panels depends on the specific needs of the cleanroom project.

If you have any questions or demands on cleanroom panels, please feel free to visit us at contact@willsoncleanroom.com Thanks!